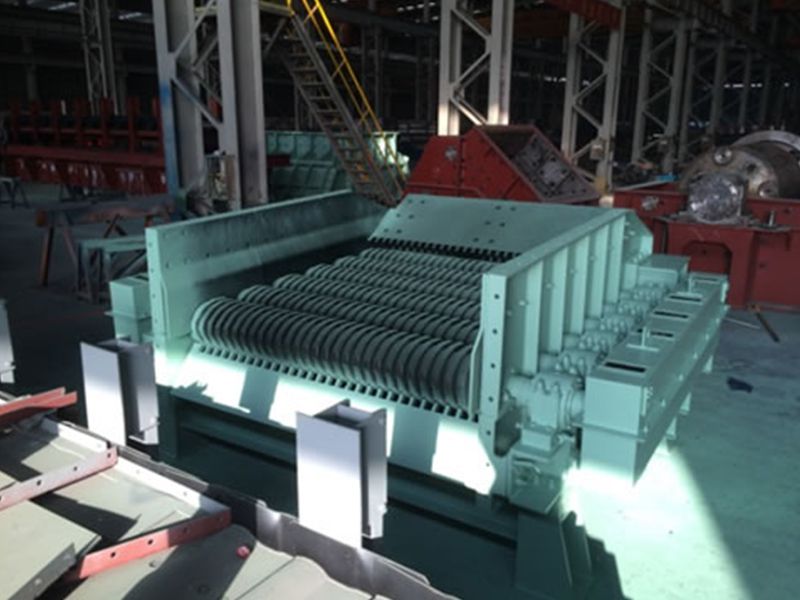

Wobbler Feeder

Wobbler Feeder

The apron pan feeder has a feeding function, and can also screen material. Customers can pair the apron pan feeder with various crushers in order to achieve continuous feeding, and the characteristics include the ability the improve material purity that is entering the crusher after shaking and mud removal, the ability to reduce the crusher burden, and prevent the crusher from being blocked. This ensures a longer equipment service life, and improves the production efficiency. Apron pan feeders are suitable for feeding and pre-sieving of muddy materials. The feeding quantity can be automatically adjusted based on the breaker load, thus improving the breaker efficiency.

| Model | Maximum feed size(mm) | Discharge size (mm) (10% of the remaining sieve) | Effective width of the trough(mm) | Length of the trough(mm) | Production capacity(t/h) |

| 600 | 50-80 | 1236 | 3650 | 150-350 | |

| 600 | 50-80 | 1236 | 5160 | 150-350 | |

| 800 | 50-80 | 1526 | 3650 | 350-450 | |

| 800 | 50-80 | 1236 | 5160 | 150-350 | |

| 1000 | 50-80 | 1826 | 5160 | 500-900 | |

| 1250 | 50-80 | 2400 | 2400 | 1000-1400 |

- The roller feeder is a multi-roller conveying machine where each roller rotates in the same direction, so the ore supported on the rollers can be sent from one end to the other. Each roller has a rib, with a gap between adjacent rollers to facilitate material discharge that don’t need to be broken down.

- The feeding roller speed can be adjusted using the frequency converter, and the speed is adjustable according to the crusher load.

- The roller feeder is used for conveying and screening materials before they are crushed. It is also suitable for materials with a high mud content.

- The roller feeder is easy to install and maintain, even in a variety of topographical conditions.

SINOMALY is an integrated engineering-procurement-construction (EPC) services provider within the cement industry, with our primary services including consultation, evaluation, planning, engineering design, procurement, project management, construction, equipment installation, and debugging.

Contact with the experts at SINOMALY to discuss how we can help you with your projects from start to finish.